High-precision dispensing facilitated by efficient degassing

Dissolved gasses present a challenge in most liquid handling situations since off-gassing and the resulting formation of bubbles typically leads to inaccurate results. This is especially troublesome in high-precision dispensing equipment, where exact volumes of chilled solutions must be distributed at high speed during long sequences. The presence of temperature gradients and pressure differences in these setups accelerates bubble formation, which immediately impacts volume accuracy to an unacceptable level. Dispensers are therefore often furnished with alarms that stop and divert the flow if bubbles are detected, which instantly has a negative impact on throughput and productivity.

The most efficient way to reduce formation of bubbles is to resolve the root cause of the problem by removing the excess of dissolved gasses. This is efficiently accomplished by an in-line degasser where a controlled vacuum withdraws dissolved gasses through a gas-permeable membrane that do not allow liquids to pass. The wide range of Biotech DEGASi® Plus degassers offers flexibility since they are designed to meet several different requirements in terms of volumes, flow rates and solvent compatibility.

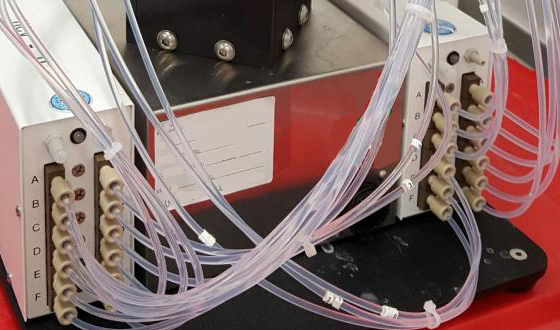

The number of daily bubble alarms during dispensing in a production machine carrying nine positive-displacement precision syringes was significantly reduced when the apparatus was equipped with two Biotech DEGASi® Plus SEMI-PREP 6-channel degassing units. The average number of daily dispensing alarms decreased by nearly 80% when using a degasser and reached a level where this did not significantly disturb the productivity, as displayed in the figure below.