NO TROUBLES WITH BUBBLES®

Degassing & Debubbling

Why degassing?

Gases dissolved in liquids often cause troubles in fluidic systems. The gas molecules can form bubbles when pressure or temperature changes, and this will affect the accuracy, precision and performance of the equipment.

Inline degassing efficiently removes dissolved gases from the fluid stream and thereby prevents bubble formation, reduces noise, improves baseline stability, reduces startup times and ensures more consistent results. This is very important in laboratory analysis equipment such as liquid chromatography, HPLC, UHPLC, ion chromatography and mass spectrometry. Machines for semi-conductor manufacturing or assembly, and instruments for immunology, hematology, and in vitro diagnostics, will also typically deliver more consistent results with a degasser included in the fluid path.

Inline degassing

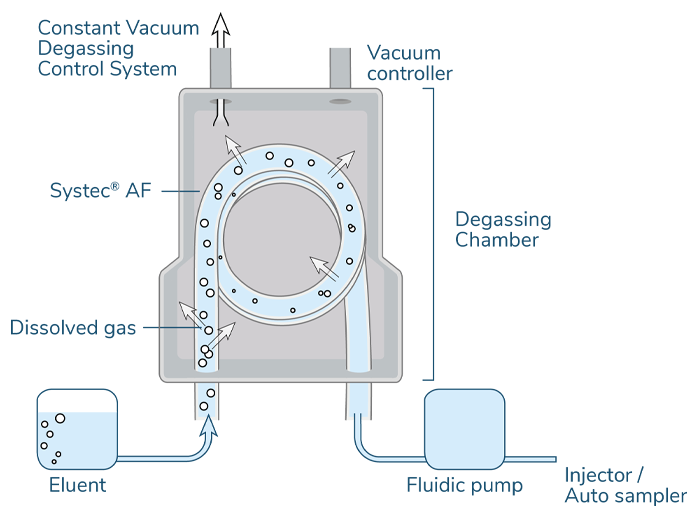

Inline degassing is accomplished by pumping liquid through a gas-permeable tubular membrane positioned in a degassing chamber exposed to vacuum. Optimum vacuum degassing performance is achieved with a membrane having high gas-permeability. This ensures efficient and continuous gas removal, even if the liquids are transported through the degassing chamber at high flow rates. For highest user-comfort and long lifetime of the degasser, it is also important to have an intelligently regulated vacuum pump that always operate at optimum speed.

Debubbling – How it works

A debubbler is a simple tool for removal of visible bubbles from water-based liquid flow streams. The legacy debubbler design explained in the video below, resulted in significant reduction of bubbles and thus improved volume delivery precision. Nowadays, debubblers have been replaced by inline degassers, thereby removing the root cause of bubble formation.

Degassing – How it works

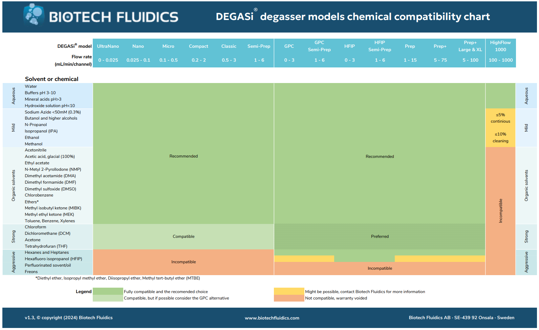

Efficient degassing requires high-quality components. The DEGASi® family of degassers are based on patented, cutting-edge vacuum pump and regulation technology, combined with highly efficient Systec™ AF gas-permeable membranes. Watch the video below to learn how inline vacuum degassing can help you to secure your analysis.

Why isn’t debubbling and ultrasonication sufficient?

Traditional and still rather widespread means to remove bubbles and dissolved gases are debubbling and ultrasonication. The problem is that none of these approaches are particularly efficient.

Debubbling removes only the gases that have outgassed into visible bubbles. Since this approach do not address the root cause of bubble formation, the remaining dissolved gases will likely form bubbles again and cause issues with precision in the liquid handling system. Ultrasonication typically removes about one third of the dissolved gases, and while this may reduce the tendency of bubble formation, it is often not sufficient to entirely prevent formation of bubbles. In contrast will vacuum degassing remove up to about 80% of the dissolved gases, which tend to totally eliminate any troubles with bubbles. Because of this, inline vacuum degassing is replacing inefficient approaches like debubbling and ultrasonication.