Inlet filters

Inlet filters prevents dust and other foreign particulate matters from entering the flow path of your liquid chromatography and (U)HPLC instrument. Such particles would otherwise eventually reach the column inlet, increase the system backpressure and might then also introduce radial flow heterogeneity which could affect peak shape. Naturally, other types of high-precision liquid handling systems can also benefit from preventing particles to reach and accumulate internally at sensitive locations.

The traditional inlet filter designs will always leave a certain amount of liquid that cannot be aspirated from the bottle. Conversely, the Bottom-of-the-Bottle™ design will make it possible to use your solvent very efficiently down to the last few millimetres from the bottom of your bottle. Regardless of the design, replacement of inlet filters should be performed regularly to prevent problems associated with filter clogging.

Biotech Fluidics offers a range of competently designed inlet filters in different materials and porosities for a variety of solvents and requirements. All of these have a defined homogenous pore size to effectively block particles above a certain size, while letting the aspirated liquid through without significant pressure drop.

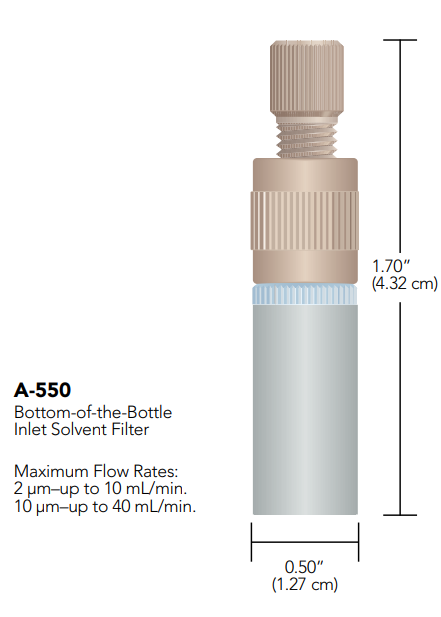

Stainless-steel Bottom-of-the-Bottle™ inlet filters

The patented stainless-steel Bottom-of-the-Bottle Solvent Filter Assemblies feature a 2 µm or 10 µm replaceable stainless steel filter cup and a design that allows solvent to be drawn from within 3.2 mm (1/8 inch) of the bottom of your solvent bottle. The filter cups are inexpensive and easy to replace, making this an economical, trouble-free choice.

- Draws solvent from within 3.2 mm of the bottom of the bottle

- Replaceable stainless steel filter cups

- Materials of construction: PEEK, ETFE, and 316 stainless-steel

- Flow rates up to 40 mL/min (10 µm filter) or 10 mL/min (2 µm filter)

| Prod. No.* | Description | Porosity | For Tubing Size | Includes | Max Flow Rate |

|---|---|---|---|---|---|

| A-550 | SST Filter Assembly, with A-520 filter cup | 10 µm | 1/8” OD | P-130, P-300 | 40 mL/min |

| A-551 | SST Filter Assembly, with A-522 filter cup | 2 µm | 1/8” OD | P-130, P-300 | 10 mL/min |

| A-520 | SST Replacement Solvent Filter Cups | 10 µm | - | - | 40 mL/min |

| A-522 | SST Replacement Solvent Filter Cups | 2 µm | - | - | 10 mL/min |

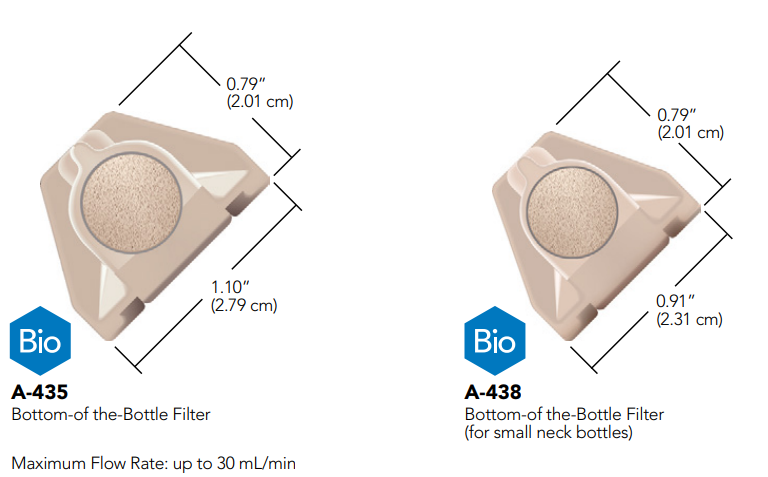

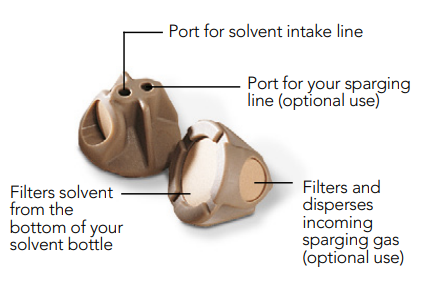

All-PEEK Bottom-of-the-Bottle™ inlet filters

These biocompatible filters are made from 100% PEEK polymer, including the two built-in PEEK frits. The bottom frit (2 µm or 10 µm) will draw solvents from within 2.0 mm (0.080 inch) of the bottom of the solvent bottle. The 2 µm frit on the side may be used for a 1/8” OD helium sparging line. To use, simply press fit your appropriately sized fluoropolymer tubing firmly into the top holes. That’s it!

- Most recommended filtering unit

- 100% PEEK polymer construction

- Easy operation — no fittings required

- Flow rates up to 30 mL/min

| Prod. No.* | Description | Porosity | For Tubing Size | Includes | Max Flow Rate |

|---|---|---|---|---|---|

| A-437 | PEEK Filter, for small-neck (GL-38) bottles | 2 µm | 1/8” OD | - | 30 mL/min |

| A-438 | PEEK Filter, for small-neck (GL-38) bottles | 10 µm | 1/8” OD | - | 30 mL/min |

Note that the item A-435 displayed above is no longer available. The recommended replacement for this is A-437 which has a smaller size and thus somewhat reduced filtration area, but otherwise similar specifications. Also items A-440, A-441, and A-451 are obsolete and the recommended replacement for them is A-438.

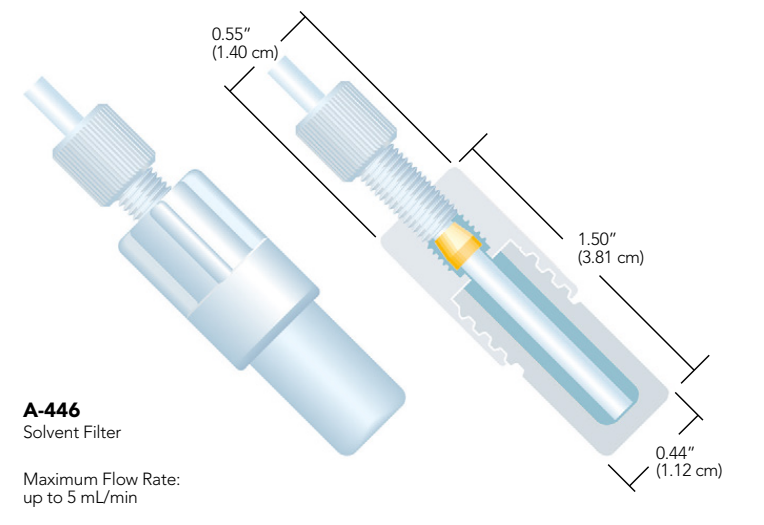

UHMWPE Bottom-of-the-Bottle™ inlet filters

The design of the UHMWPE solvent filters allows tubing to pass through to the bottom of the filter cup, enabling the filter to draw solvent from within 2.5 mm (0.10 inch) of the bottom of your solvent bottle. Note that UHMWPE is a hydrophobic material, and to establish proper surface wetting, you may need to prime the filter with methanol or acetonitrile.

- Replaceable filter cup

- Economical

- Materials of construction: UHMWPE, ETFE

- Versions for 1/16” and 1/8” OD tubing

- Flow rates up to 5 mL/min

| Prod. No.* | Description | Porosity | For Tubing Size | Includes | Max Flow Rate |

|---|---|---|---|---|---|

| A-445 | UHMWPE Filter Assembly | 10 µm | 1/16” OD | P-245, P-200 | 5 mL/min |

| A-446 | UHMWPE Filter Assembly | 10 µm | 1/8” OD | P-345, P-300 | 5 mL/min |

| A-427 | UHMWPE Replacement Solvent Filter Cups, 5-pk | 10 µm | - | - | 5 mL/min |

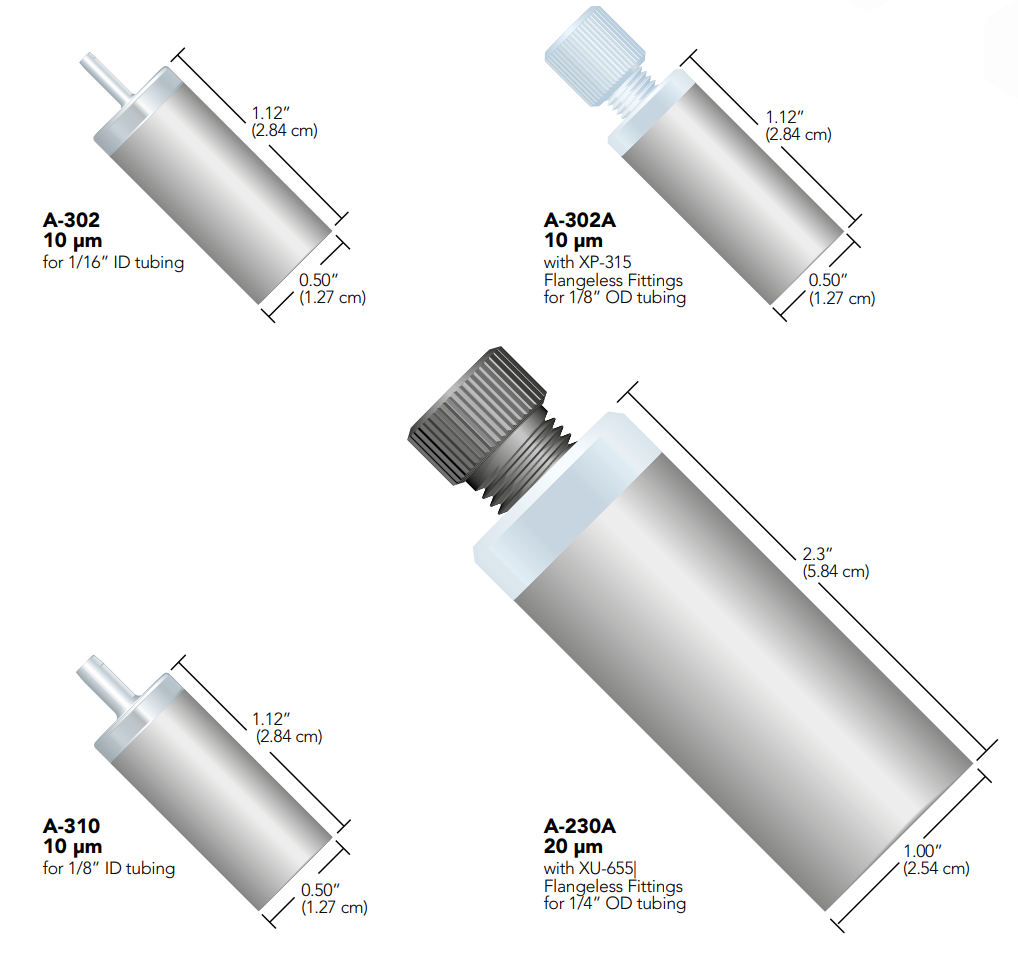

Traditional stainless-steel inlet filters

The traditional 316 stainless-steel inlet filters can be used for several purposes. To protect your pump system from damage by foreign particles the 10 or 20 µm porosity is typically recommended. To filter out particulate matter from the solvent that may otherwise damage expensive hardware, a filter with 10 µm or 20 µm porosity is typically used. To prevent particulates originating from the sparging system from entering the mobile phase reservoir and to help disperse the sparging gas efficiently, we recommend 2 µm filter porosity. To hold just the tubing in place at the bottom of the bottle, most porosity options work.

Note that the filter surface area and porosity might restrict how high flow rates can be used without risking cavitation due to pressure drop. These inlet filters either come with a stem to slide into the tubing end (for ID 1/16” or 1/8”) or a low-pressure flangeless fitting (for OD 1/8”, or 3/16”, or 1/4″).

- Disposable

- Large surface areas prevent pump cavitation

- 2 µm, 10 µm, and 20 µm pore sizes available

- General use and prep filters for higher flow applications

| Prod. No.* | Description | Porosity | Material | For Tubing Size | Includes | Max Flow Rate |

|---|---|---|---|---|---|---|

| A-242 | Analytical Inlet Solvent Filter with One-Piece Fitting | 2 µm | PCTFE, SST | 1/8” OD | P-100 | 10 mL/min |

| A-243 | A-242, 5-pack | 2 µm | PCTFE, SST | 1/8” OD | P-100 (5 ea) | 10 mL/min |

| A-302A | Analytical Inlet Solvent Filter with Flangeless Fitting | 10 µm | PCTFE, SST | 1/8” OD | P-315, P-300 | 40 mL/min |

| A-231A | Analytical Inlet Solvent Filter with Flangeless Fitting | 20 µm | PCTFE, SST | 3/16” OD | P-132, P-133 | 100 mL/min |

| A-225A | Preparative Inlet Solvent Filter with Flangeless Fitting | 20 µm | PCTFE, SST | 1/8” OD | P-315, P-300N | 100 mL/min |

| A-227A | Preparative Inlet Solvent Filter with Flangeless Fitting | 10 µm | PCTFE, SST | 1/4” OD | U-655, U-650 | 100 mL/min |

| A-230A | Preparative Inlet Solvent Filter with Flangeless Fitting | 20 µm | PCTFE, SST | 1/4” OD | U-655, U-650 | 100 mL/min |

| A-311A | Preparative Inlet Solvent Filter with Flangeless Fitting | 10 µm | PCTFE, SST | 1/8” OD | P-315, P-300 | 100 mL/min |

| Prod. No.* | Description | Porosity | Material | For Tubing Size | Includes | Max Flow Rate |

|---|---|---|---|---|---|---|

| A-302 | Analytical Inlet Solvent Filter with stem | 10 µm | SST | 1/16” ID | - | 40 mL/min |

| A-309 | Analytical Inlet Solvent Filter with stem | 10 µm | SST | 1/16” ID | - | 40 mL/min |

| A-310 | Analytical Inlet Solvent Filter with stem | 10 µm | SST | 1/8” ID | - | 40 mL/min |

| A-225 | Preparative Inlet Solvent Filter with stem | 20 µm | SST | 1/16” ID | - | 100 mL/min |

| A-311 | Preparative Inlet Solvent Filter with stem | 10 µm | SST | 1/16” ID | - | 100 mL/min |