Reaction delay coils

Tubular reaction delay and constant mixing coils for plug flows

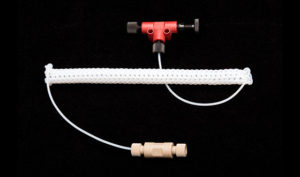

The Reaction Delay Coils are reactors made from PTFE tubing knitted into a tortuous path to force the fast moving centre of the liquid stream to mix radially with the slower moving boundary liquid layer. This technique minimizes the axial dispersion. The shape of a chromatographic peak entering the reactor is in this way preserved efficiently. The Reaction Delay Coil is the most optimal delay element for use in any plug flow systems. It is typically inserted in the flow path to create a delay so that a reaction that requires a certain time can take place. Reaction Delay Coils are also known as Knitted Open Tubular Reactors, or KOT reactors for short.

- Peak shapes maintained

- Reaction time 10-100 seconds

- In PTFE for full chemical resistance

- Customisations available on demand

The concept of constant mixing

The Reaction Delay Coils are made from tubing knitted into a tortuous path to force the fast moving center of the liquid stream to mix radially with the slower moving boundary liquid layer. The constant mixing minimizes the axial dispersion and maintains the shape of the chromatographic peak entering the reactor efficiently. The reactor is typically inserted in the flow path to create a delay providing time for the expected reaction. Different reaction times are accomplished by changing the inner diameter and length of the Reaction Delay Coil (a.k.a. KOT reactor). To ensure a stable radial mixing a linear flow rate of 10 cm/s or more is recommended.

Application examples

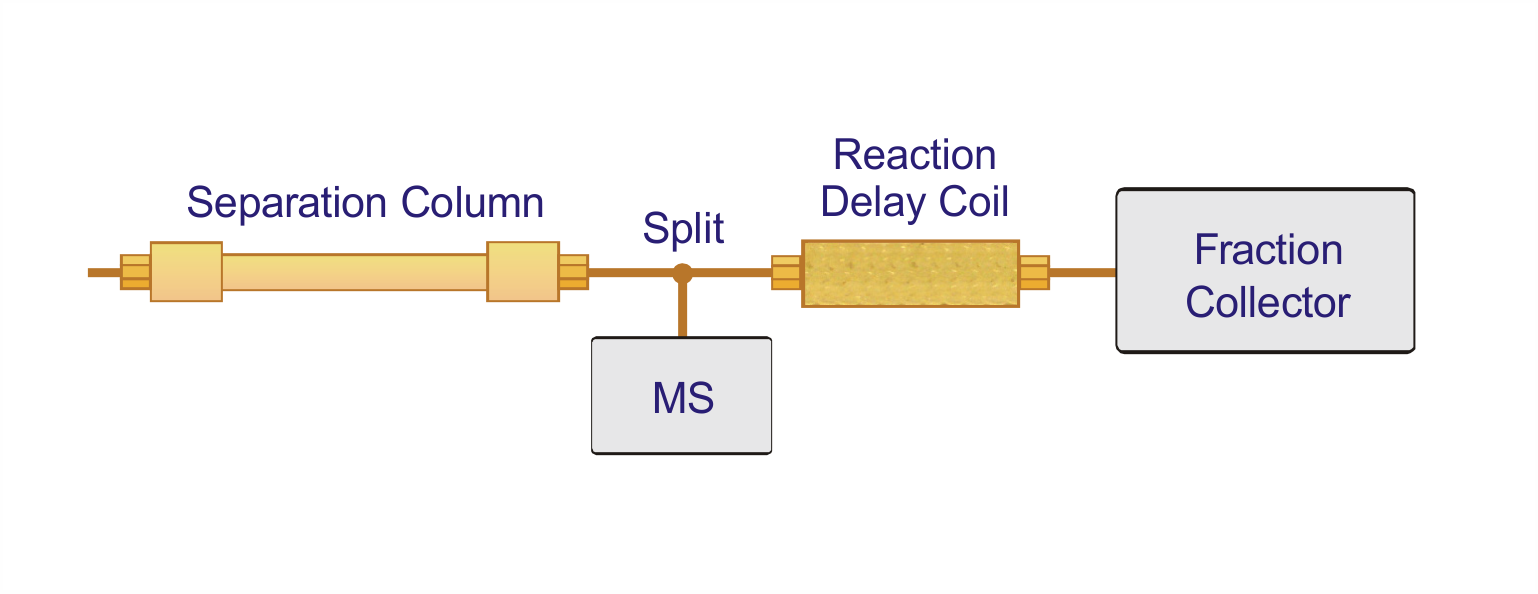

Post prep column delay

The Reaction Delay Coil can be applied as a delay in the parallel coupling of a MS detector and a fraction collector in preparative separations. The delay time induced by the Reaction Delay Coil allows the detector to analyse the eluate and make intelligent decisions of when a new fraction is going to be initiated, without loss of chromatographic efficiency.

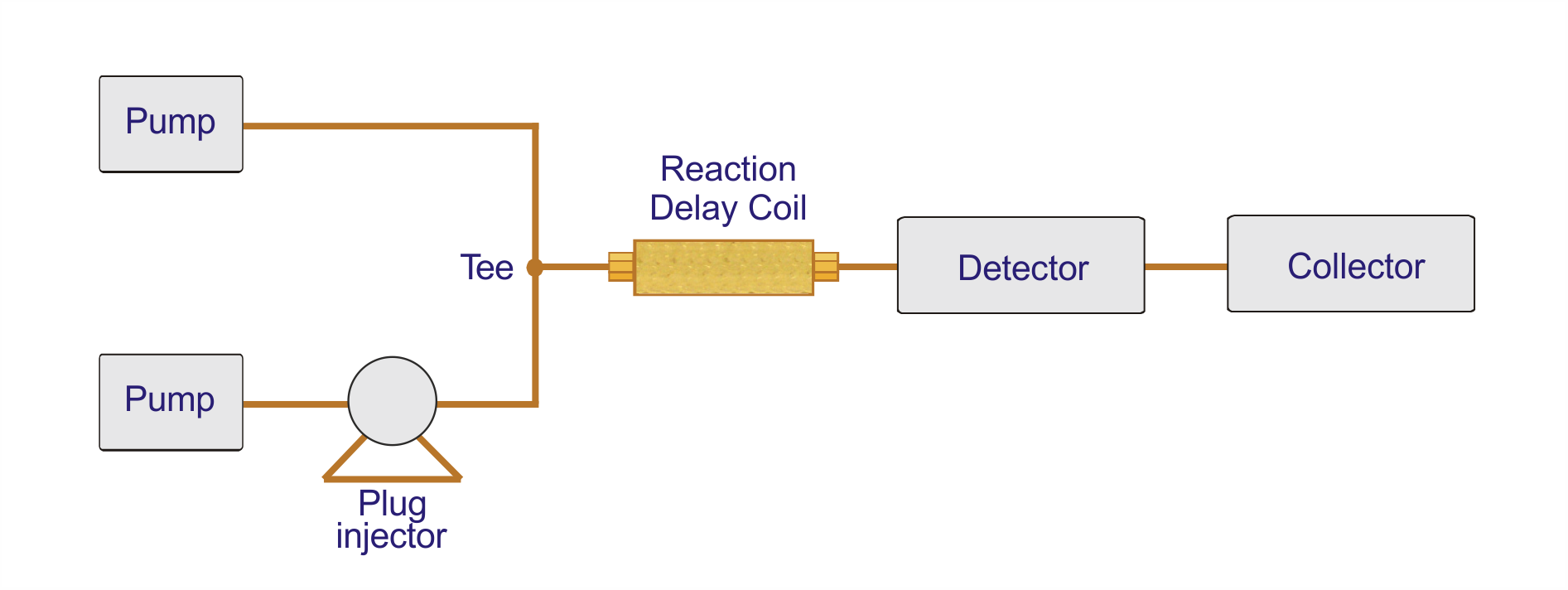

Scouting continuous processes

The Reaction Delay Coil is the perfect tool for optimising flow chemistry applications based on plug injections. Precious substrate can be saved without compromising the number of conditions to be investigated. In this way the Reaction Delay Coil offers the user to do more experiments establishing better reaction conditions on less raw material.

Technical data

The Reaction Delay Coils are manufactured from high-quality virgin PTFE. Other tubing materials or alternative shapes can be available upon request. To maintain a proper mixing a linear flow rate of on less than 10 cm/s is recommended. Max recommended pressure relates to the tubing in the coil and not to connecting fittings. Biotech Fluidics can provide you with any needed fitting. Each Reaction Delay Coil comes with a serial number providing full traceability.

| Part No. | Reaction Delay Coil (a.k.a. KOT) | L (m) | ID (mm) | Volume (mL) | Flow rate (mL/min) * | Residence time (s) ** | Pressure (bar) *** |

|---|---|---|---|---|---|---|---|

| 3000-123 | Knitted coil PTFE | 1 | 0.25 | 0.05 | 0.29 | 10 | 100 |

| 3000-125 | Knitted coil PTFE | 1 | 0.5 | 0.20 | 1.2 | 10 | 70 |

| 3000-128 | Knitted coil PTFE | 1 | 0.75 | 0.44 | 2.7 | 10 | 30 |

| 3000-223 | Knitted coil PTFE | 2 | 0.25 | 0.10 | 0.29 | 20 | 100 |

| 3000-225 | Knitted coil PTFE | 2 | 0.5 | 0.39 | 1.2 | 20 | 70 |

| 3000-228 | Knitted coil PTFE | 2 | 0.75 | 0.88 | 2.7 | 20 | 30 |

| 3000-423 | Knitted coil PTFE | 4 | 0.25 | 0.20 | 0.29 | 40 | 100 |

| 3000-425 | Knitted coil PTFE | 4 | 0.5 | 0.79 | 1.2 | 40 | 70 |

| 3000-428 | Knitted coil PTFE | 4 | 0.75 | 1.77 | 2.7 | 40 | 30 |

| 3000-523 | Knitted coil PTFE | 5 | 0.25 | 0.25 | 0.29 | 50 | 100 |

| 3000-525 | Knitted coil PTFE | 5 | 0.5 | 0.98 | 1.2 | 50 | 70 |

| 3000-528 | Knitted coil PTFE | 5 | 0.75 | 2.21 | 2.7 | 50 | 30 |

| 3000-133 | Knitted coil PTFE | 10 | 0.25 | 0.49 | 0.29 | 100 | 100 |

| 3000-135 | Knitted coil PTFE | 10 | 0.5 | 1.96 | 1.2 | 100 | 70 |

| 3000-138 | Knitted coil PTFE | 10 | 0.75 | 4.42 | 2.7 | 100 | 30 |

| *Recommended minimum flow rate to achieve proper mixing by maintaining the linear flow rate ≥10cm/s. **Residence time at minimum flow rate. ***Maximum operational pressure - note that selected fittings may affect pressure rating. | |||||||