Flow regulating valves

Biotech Fluidics provides several types of flow regulating valves, including a wide range of different inline check valves that will prevent liquid from flowing in the wrong direction. In addition, Biotech Fluidics deliver shut-off valves to manually turn off fluid lines, plus splitter valves that divide the fluid stream into two sections, and metering valves that can restrict the total flow rate by providing a variable back pressure.

- Inline check valves

- Shut-off valves

- Splitter valves

- Metering valves

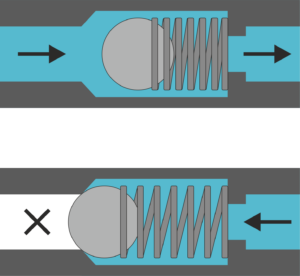

Inline check valves are designed to allow fluid flow only in one direction, while preventing it in the opposite direction. This is an effective way to eliminate back flow and thereby safeguard sensitive components and prevent contamination of reagent reservoirs within a fluidic system. The construction of check valves differs between models but the principle of all is the same, and this sketch shows a spring-assisted ball check valve to illustrate the working principle.

All check valves require a certain pressure to open in the allowed flow direction and this is referred to as the cracking pressure. Another important pressure specification is the total pressure limit, above which the check valve might start to leak in the backward direction, or even suffer structural damage, wherefore it never should be exceeded.

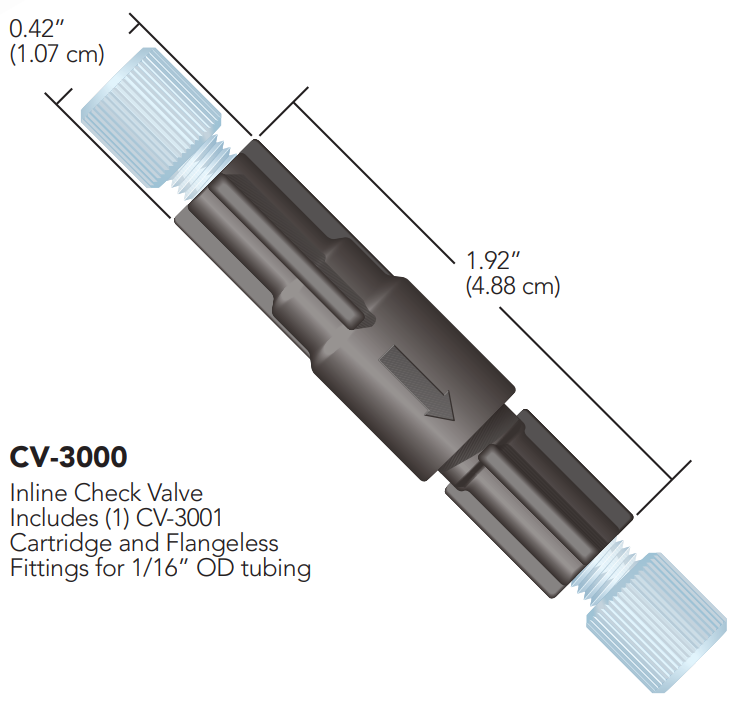

Inline Cartridge Check Valves

The cartridge-style Inline Check Valves are designed to limit flow to one direction. These assemblies withstand system pressures of 1,000 psi (69 bar). The cracking pressures for the Inline Check Valve Cartridges are 1.5 psi (0.1 bar) for the CV-3001 and 3 psi (0.2 bar) for the CV-3011. Tolerance on the cracking pressure for CV-3001 is ± 0.5 psi (0.03 bar) and ± 1.5 psi (0.1 bar) on CV-3011.

Materials of construction: PEEK; perfluoroelastomer (CV-3001); gold-plated stainless steel spring (CV-3001); ethylene propylene (CV-3011); and stainless steel spring (CV-3011)

| Prod. No.* | Description | Swept Volume | Includes |

|---|---|---|---|

| CV-3000 | Inline Check Valve Assembly for 1/16” OD tubing | 96 µL | CV-3001, P-215 (2), P-200 (2) |

| CV-3001 | Inline Check Valve Cartridge for CV-3000 | 91 µL | - |

| CV-3010 | Inline Check Valve Assembly for 1/8” OD tubing | 100 µL | CV-3011, P-315 (2), P-300 (2) |

| CV-3011 | Inline Check Valve Cartridge for CV-3010 | 95 µL | - |

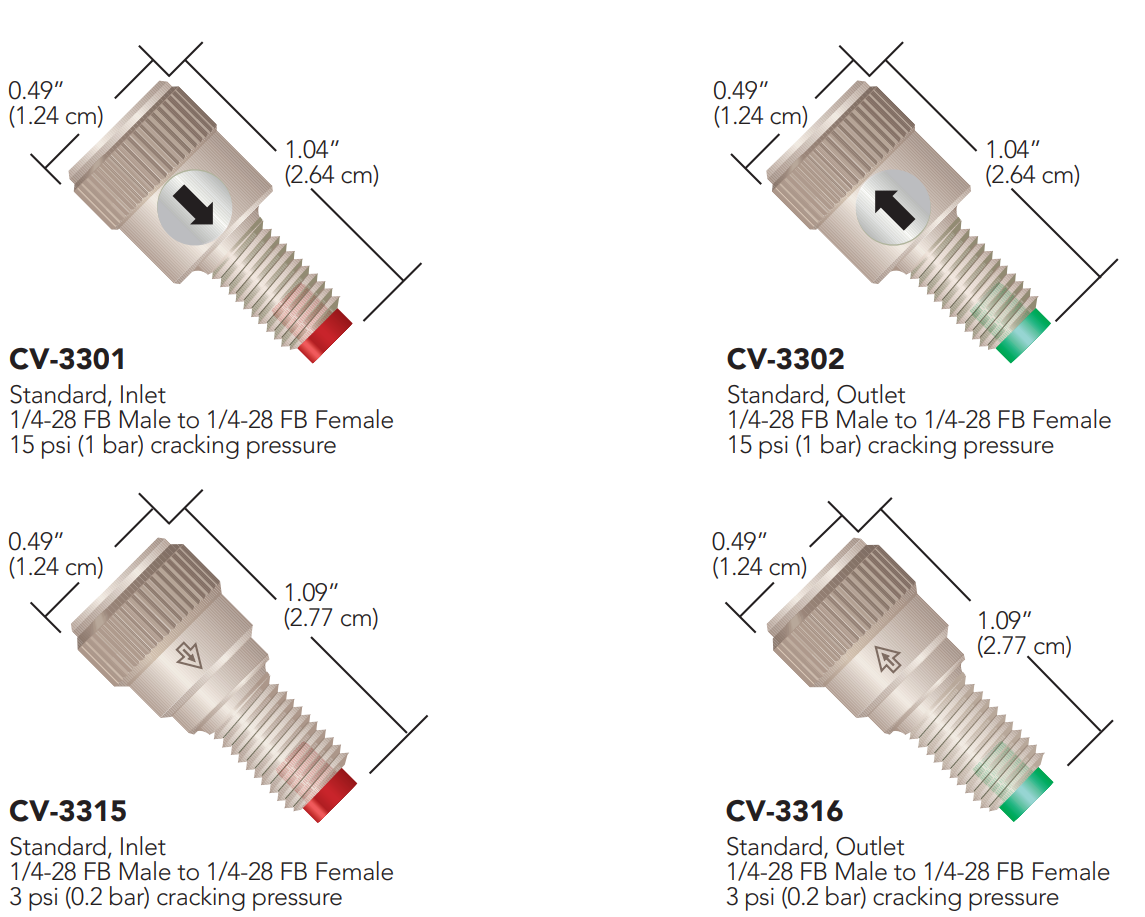

Standard 1/4-28 Inline Check Valves

Connect these Inline Check Valves to any 1/4-28 flat-bottom port. Then thread your 1/4-28 flat-bottom fitting into the check valve to connect the tubing. Once installed, the spring-actuated sealing system eliminates back flow, helping to prevent upstream contamination or damage. In addition, the unique design of this product eliminates the additional tubing cuts and connections required to install conventional inline check valves.

The back pressure created by the check valves at a flow rate of 50 mL/min room temperature water, is 45 psi (3.1 bar) for CV-3301 & CV-3302, whereas it is 10 psi (0.7 bar) for CV-3315 & CV-3316. They can withstand a pressure up to 2,000 psi (138 bar) before backward leaking starts. The cracking pressure for CV-3301 & CV-3302 is 15 psi (1 bar) with a tolerance of ± 5 psi (0.34 bar), whereas it is 3 psi (0.2 bar) with a tolerance of ± 1.5 psi (0.10 bar) for CV-3315 & CV-3316.

Materials of construction: PEEK; PCTFE; perfluoroelastomer; PTFE (CV-3301 and CV-3302); stainless steel (CV-3301 and CV-3302); or gold-plated stainless steel (CV-3315 and CV-3316)

| Prod. No.* | Description** | Cracking Pressure | Thru-Hole | Swept Volume | Pressure Rating |

|---|---|---|---|---|---|

| CV-3301 | Inlet Check Valve, 1/4-28 FB, M to 1/4-28 FB, F | 15 psi (1 bar) | 0.020” (0.50 mm) | 20 µL | 2,000 psi (138 bar) |

| CV-3302 | Outlet Check Valve, 1/4-28 FB, M to 1/4-28 FB, F | 15 psi (1 bar) | 0.020” (0.50 mm) | 20 µL | 2,000 psi (138 bar) |

| CV-3315 | Inlet Check Valve, 1/4-28 FB, M to 1/4-28 FB, F | 3 psi (0.2 bar) | 0.020” (0.50 mm) | 16 µL | 2,000 psi (138 bar) |

| CV-3316 | Outlet Check Valve, 1/4-28 FB, M to 1/4-28 FB, F | 3 psi (0.2 bar) | 0.020” (0.50 mm) | 16 µL | 2,000 psi (138 bar) |

| **F = Female (internal) threads; M = Male (external) threads; C = Coned; FB = Flat-Bottom | |||||

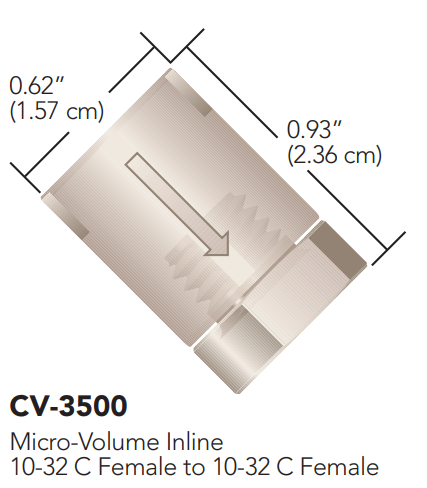

Non-metallic 10-32 Micro-Volume Inline Check Valve

The 10-32 Non-Metallic Micro-Volume Check Valves are biocompatible and delivers a low cracking pressure. With a swept volume of only 7.4 µL, our 10-32 Micro-Volume Inline Check Valves are perfect for applications where low flow path volume is critical, such as delivery to lab-on-a-chip, single-cell analysis and micro- or nano-LC post-column derivatization. Once installed, this check valve helps prevent back flow and the potential for contamination or damage to sensitive upstream equipment.

The back pressure created by this check valve is 25 psi (1.7 bar) at a flow rate of 50 mL/min room temperature water. It can withstand a pressure up to 3,000 psi (207 bar) before backward leaking starts. The cracking pressure is 8 psi (0.6 bar) with a tolerance of ± 5 psi (0.34 bar).

| Prod. No.* | Description** | Cracking Pressure | Thru-Hole | Swept Volume | Pressure Rating |

|---|---|---|---|---|---|

| CV-3500 | Inlet/Outlet Check Valve, 10-32 C, F to 10-32 C, F | 8 psi (0.6 bar) | 0.010” (0.25 mm) | 7.4 µL | 3,000 psi (207 bar) |

| **F = Female (internal) threads; M = Male (external) threads; C = Coned; FB = Flat-Bottom | |||||

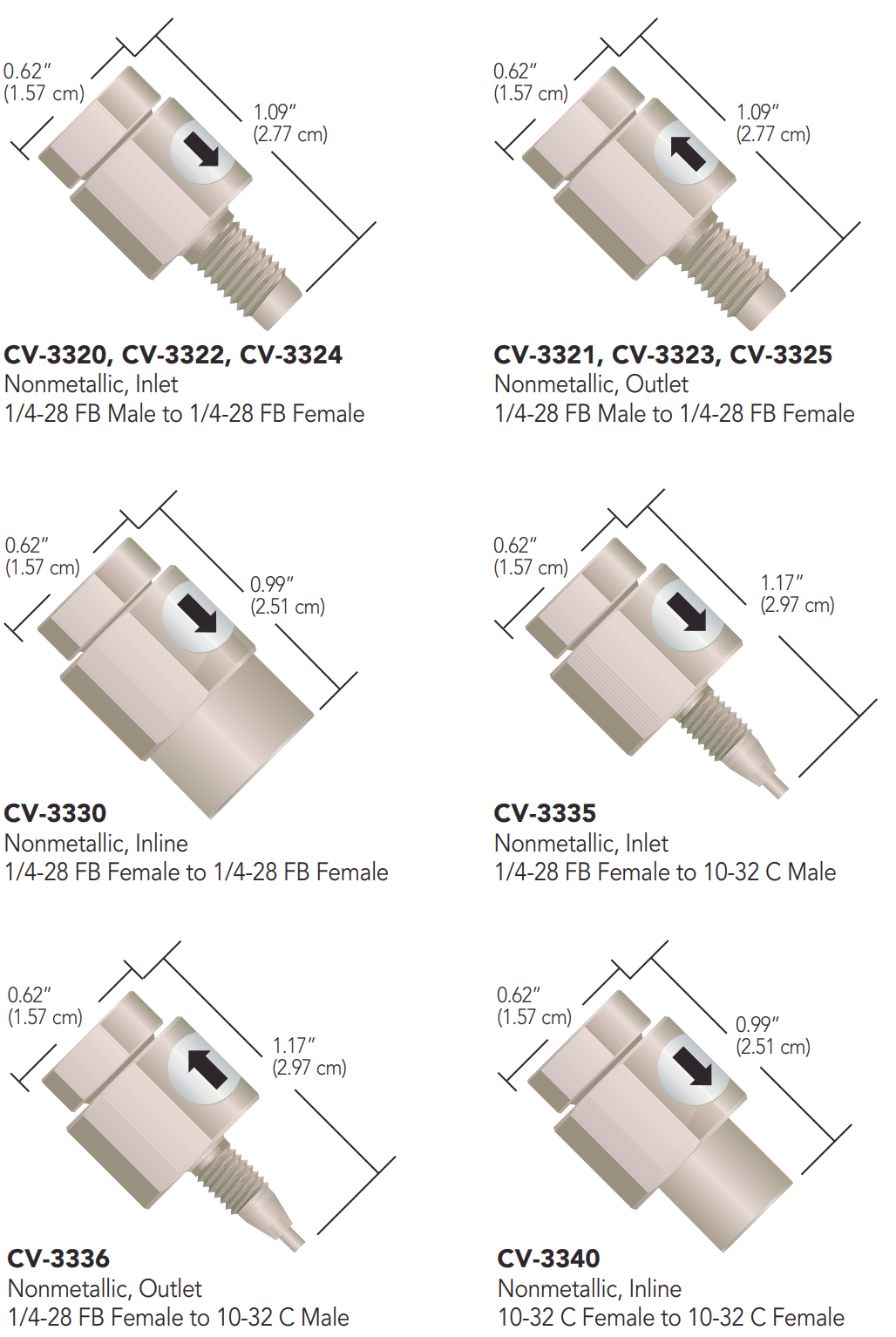

Non-metallic 1/4-28 & 10-32 Inline Check Valves

The Biocompatible 1/4-28 & 10-32 Non-Metallic Inline Check Valves provide excellent backflow protection for sensitive equipment along with outstanding chemical resistance guaranteed by the PEEK polymer and perfluoroelastomer construction. Metal-free composition makes these check valves perfect for use with corrosive fluids or biological samples.

These check valves function well up to moderately-high pressure applications. Low internal volume also allows them to be used in areas where flow path volume is important; however, higher flow rates can pass through with minimal pressure drop.

The back pressure created by these check valves is 30 psi (2.1 bar) at a flow rate of 50 mL/min room temperature water. They can withstand a pressure up to 2,000 psi (138 bar) before backward leaking starts. Their cracking pressure is 1 psi (0.07 bar) with a tolerance of ± 0.5 psi (0.03 bar). Note that upon initial use, or following a period of extended inactivity, the cracking pressure for these check valves may be somewhat higher than the stated cracking pressure.

| Prod. No.* | Description** | Cracking Pressure | Thru-Hole | Swept Volume | Pressure Rating |

|---|---|---|---|---|---|

| CV-3320 | Inlet Check Valve, 1/4-28 FB, M to 1/4-28 FB, F | 1 psi (0.07 bar) | 0.020” (0.50 mm) | 37 µL | 2,000 psi (138 bar) |

| CV-3321 | Outlet Check Valve, 1/4-28 FB, M to 1/4-28 FB, F | 1 psi (0.07 bar) | 0.020” (0.50 mm) | 37 µL | 2,000 psi (138 bar) |

| CV-3322 | Inlet Check Valve, 1/4-28 FB, M to 1/4-28 FB, F | 1 psi (0.07 bar) | 0.040” (1.0 mm) | 49 µL | 2,000 psi (138 bar) |

| CV-3323 | Outlet Check Valve, 1/4-28 FB, M to 1/4-28 FB, F | 1 psi (0.07 bar) | 0.040” (1.0 mm) | 49 µL | 2,000 psi (138 bar) |

| CV-3324 | Inlet Check Valve, 1/4-28 FB, M to 1/4-28 FB, F | 1 psi (0.07 bar) | 0.060” (1.60 mm) | 182 µL | 2,000 psi (138 bar) |

| CV-3325 | Outlet Check Valve, 1/4-28 FB, M to 1/4-28 FB, F | 1 psi (0.07 bar) | 0.060” (1.60 mm) | 182 µL | 2,000 psi (138 bar) |

| CV-3330 | Inlet/Outlet Check Valve, 1/4-28 FB, F to 1/4-28 FB, F | 1 psi (0.07 bar) | 0.020” (0.50 mm) | 34 µL | 2,000 psi (138 bar) |

| CV-3335 | Inlet Check Valve, 1/4-28 FB, F to 10-32 C, M | 1 psi (0.07 bar) | 0.020” (0.50 mm) | 49 µL | 2,000 psi (138 bar) |

| CV-3336 | Outlet Check Valve, 1/4-28 FB, F to 10-32 C, M | 1 psi (0.07 bar) | 0.020” (0.50 mm) | 49 µL | 2,000 psi (138 bar) |

| CV-3340 | Inlet/Outlet Check Valve, 10-32 C, F to 10-32 C, F | 1 psi (0.07 bar) | 0.020” (0.50 mm) | 34 µL | 2,000 psi (138 bar) |

| **F = Female (internal) threads; M = Male (external) threads; C = Coned; FB = Flat-Bottom | |||||

Quick-Stop Luer Inline Check Valve

The Quick-Stop Luer Check Valve is designed to provide inline luer connect/disconnect convenience without the mess and hazard of spills. Just connect the valve assembly to your inline tubing using standard 1/4-28 flat-bottom fittings. The check valve is automatically opened once the luer connection is engaged, allowing flow in either direction. Disconnecting the luer union causes the check valve to close.

| Prod. No.* | Description | Swept Volume | Includes |

|---|---|---|---|

| P-696 | Quick-Stop Luer Check Valve Assembly | 127 µL | P-697, P-655 |

| P-697 | Quick-Stop Luer Check Valve | 107 µL | - |

| P-699 | Bulkhead Quick-Stop Luer Valve | 107 µL | nut/lock washer set |

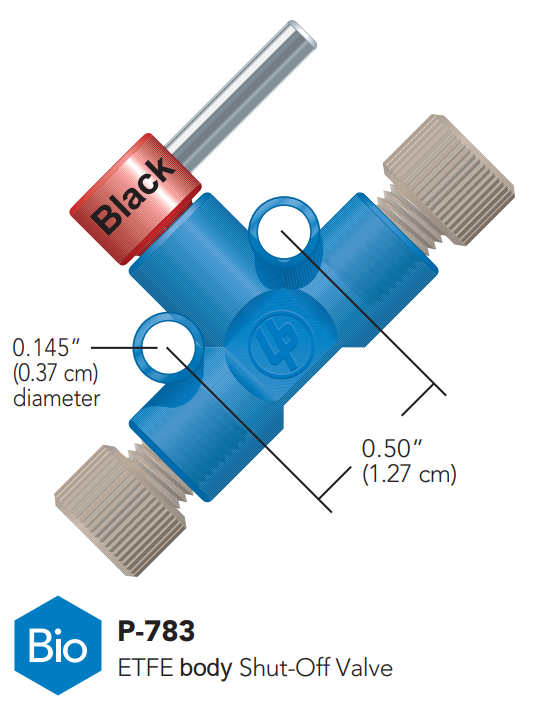

Shut-Off Valves

Stop a flow stream quickly with the biocompatible Shut-Off Valves. The bodies are manufactured from ETFE, and a PEEK rotor, making them highly resistant to chemical attack. The blue colorant used in some valve configurations has proven not to leach out with common HPLC solvents. Connect semi-rigid or rigid tubing, such as PEEK, stainless steel or fluoropolymer, with the 1/4-28 Flangeless Fittings provided. Soft tubing, such as PharMed® or Tygon®, may be connected to these valves using our 1/4-28 barbed adapters.

| Prod. No.* | Material | OD Tubing | Thru-hole | Internal Volume** | Includes |

|---|---|---|---|---|---|

| P-721 | ETFE body, PEEK rotor black | 1/8" | 0.040” (1.0 mm) | 10.0 µL | P-335 (2), P-300N (2) |

| P-782 | ETFE body, PEEK rotor black | 1/16" | 0.020” (0.5 mm) | 2.5 µL | P-235 (2), P-200 (2) |

| P-783 | ETFE body, PEEK rotor black | 1/8" | 0.040” (1.0 mm) | 10.0 µL | P-335 (2), P-300 (2) |

| **maximum internal volume, with valve fully open | |||||

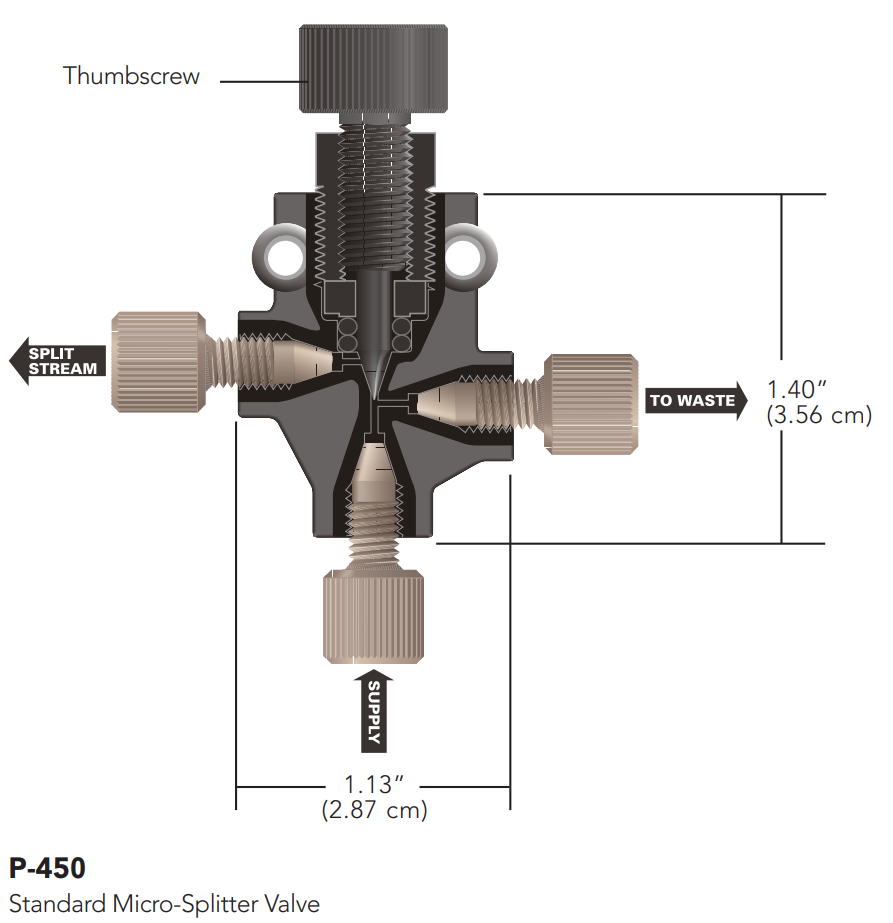

Micro-Splitter Valves

The Micro-Splitter Valves are designed to accurately split and control a low-flow stream off a single incoming supply. Choose between 1/4-28 flat-bottom and 10-32 coned threaded versions. The High Pressure Micro-Splitter Valves are designed to operate successfully up to 4,000 psi (276 bar) and the standard Micro-Splitter valves are pressure rated to 800 psi (55 bar).

The Graduated Valve offers many of the benefits and features of Micro-Splitter Valves, plus the ability to adjust and set the split flow to repeatable settings. This allows documentation of settings and the resulting flow rates for easier method development. The graduations also make it easier to employ the valve in a system used to run multiple analyses that require different split flow rates.

With an incoming flow rate of 1 mL/min using room temperature water and equal pressures on both outlet lines, the minimum split flow rate is 2 µL/min for the standard micro-splitter valves and 4.8 µL/min for the high pressure micro-splitter valves. All Micro-Splitter Valves have been tested at flow rates to 100 mL/min, with a maximum resulting pressure drop of only 45 psi (3.1 bar) when the valve is fully opened.

| Prod. No.* | Description | Threads | Internal Volume** | Max Pressure | Includes |

|---|---|---|---|---|---|

| P-450 | Standard Micro-Splitter Valve, Biocompatible | 1/4-28 | 2.1 / 4.1 µL | 800 psi (55 bar) | P-235 (3), P-200 (3) |

| P-470 | High-Pressure Micro-Splitter Valve, Graduated with Stainless Steel Needle | 10-32 | 1.2 / 2.8 µL | 4,000 psi (276 bar) | F-120 (3) |

| **referring to closed and fully open positions, respectively | |||||

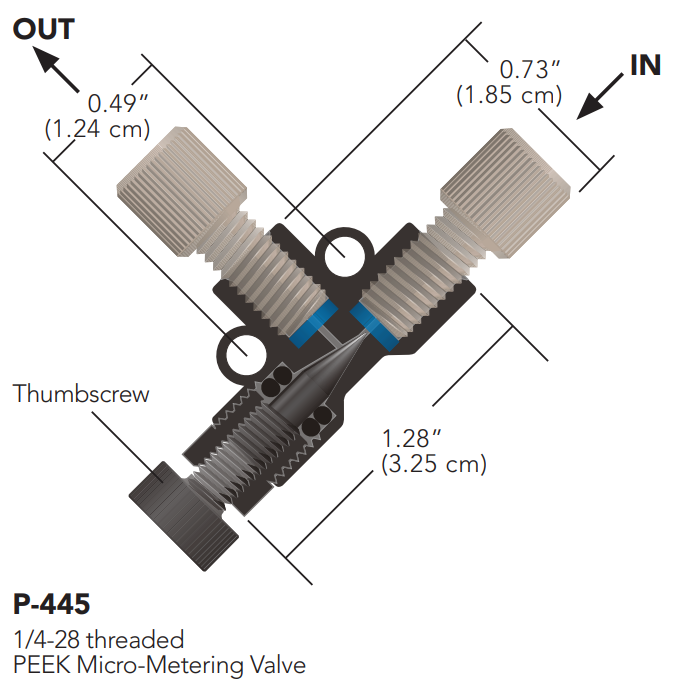

Micro-Metering Valves

For fine control of fluid flow rates, Micro-Metering Valves can reduce outgoing flow to as low as 3.5 µL/min. These needle valves are perfect for use with peristaltic pump fluid-transfer applications, mass spectrometry, and fraction collection. Our Micro-Metering Valves can also be used to regulate gas flow in helium sparging lines and as a flow-dependent variable back pressure regulator. For flow independent regulation of back pressure, please see page 147. Flow path materials are PEEK polymer and PTFE. All versions of this valve have 0.020” (0.50 mm) thru-holes.

| Prod. No.* | Material | OD Tubing | Thru-hole | Internal Volume** | Includes |

|---|---|---|---|---|---|

| P-445 | PEEK, Black | 1/16" | 0.020” (0.50 mm) | 7.7 µL | P-330 (2), P-300 (2) |

| P-446 | PEEK, Black | 1/16" | 0.020” (0.50 mm) | 7.2 µL | F-120 (2) |

| P-447 | PEEK, Black | 1/8" | 0.020” (0.50 mm) | 7.7 µL | P-330 (2), P-300 (2) |

| **maximum internal volume with valve fully open | |||||