NO TROUBLES WITH BUBBLES®

DEGASi® Preparative series

Powerful degassers for the highest flow rates

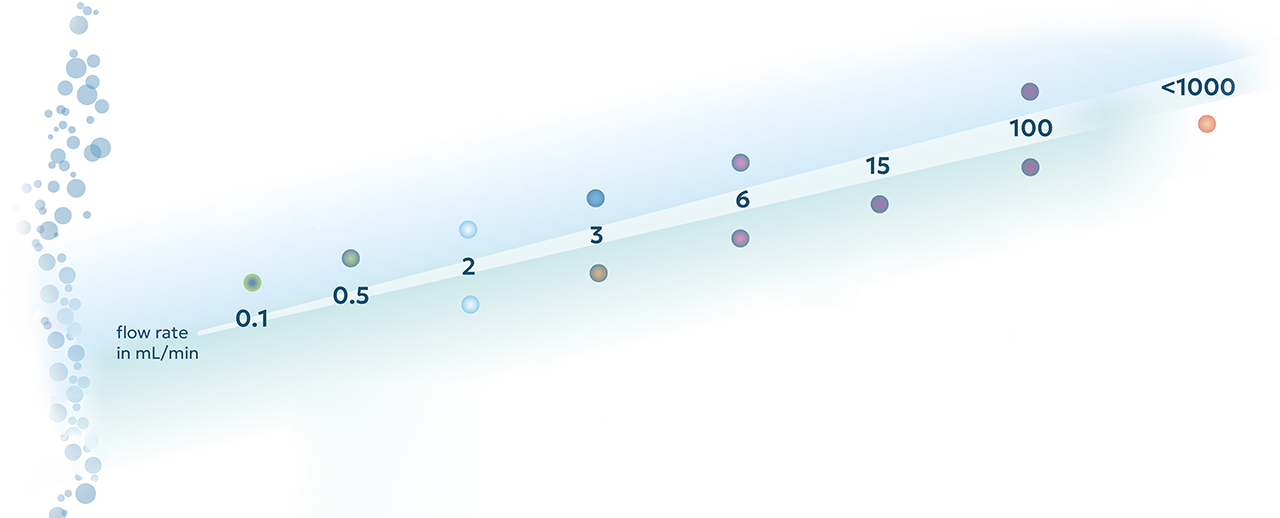

The DEGASi® Preparative series contains the most powerful stand-alone inline degassers built for the highest flow rate requirements. Degasser models in this series are suitable for high-throughput applications, including preparative HPLC, flash chromatography, dissolution testing, clinical chemistry analysers, dispensing applications, and ink degassing.

Benefits

- Very powerful

- Silent & long life expectancy

- Available with 1, 2, or 4 degassing channels (depending on model)

- Available with different port designs for different tubing diameters

- Advanced leak and error detection functions with bicolour indicator LED

- Patented closed-loop vacuum control for ultra-stable performance

- Easy troubleshooting and replacement of parts

- Short lead time

- CE & RoHS compatible

Description

Models in the DEGASi® Preparative series can be configured with 1, 2 or 4 channels, depending on model, for a wide variety of applications requiring degasification of aqueous and organic liquids at flow rates up to 100 mL/min. The DEAGSi® Prep degasser is suitable for aqueous and organic solvents at flow rates up to 15 mL/min. The different variants of DEGASi® Prep+ are the most powerful degassers for organic solvents and can be configured for tubing sizes of 1/8″, 3/16″, or 1/4″ OD. The DEGASi® Prep+ AUX has identical properties to the other DEGASi® Prep+ units, but comes equipped with an additional channel for degassing of a parallel auxiliary liquid flow in the analytical range. The DEGASi® High Flow 1000 can manage flow rates up to 1000 mL/min but is limited to water-based liquids.

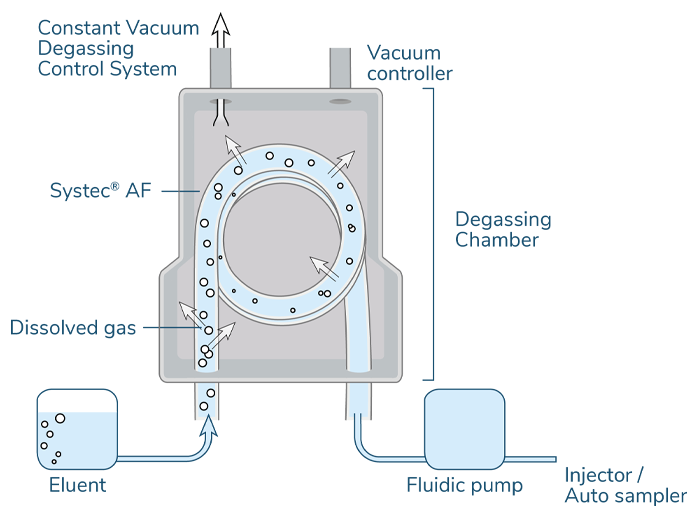

Most DEGASi® Preparative series degassers remove dissolved gases by continuous inline degassing using a constant vacuum applied over a Systec™ AF membrane that is permeable to gases but not liquids. The exception is DEGASi® High Flow 1000 which operates according to the same principle, but instead is based on a silicon membrane. The removal of dissolved gases from liquid chromatography mobile phases reduces retention time shifts and improves baseline stability, while also reducing the level of oxygen which otherwise can interfere with detection techniques such as UV absorption and fluorescence. All problems with bubbles are typically eliminated when 50% of the dissolves gases are removed, which often can be critical in analytical systems as well as dispensing applications.